Skylane Optics at ANGA COM 2024 – May 14-16 in Cologne, Germany

Products (0)

Case studies (0)

News (0)

Oups... We don’t find any results corresponding to your search.

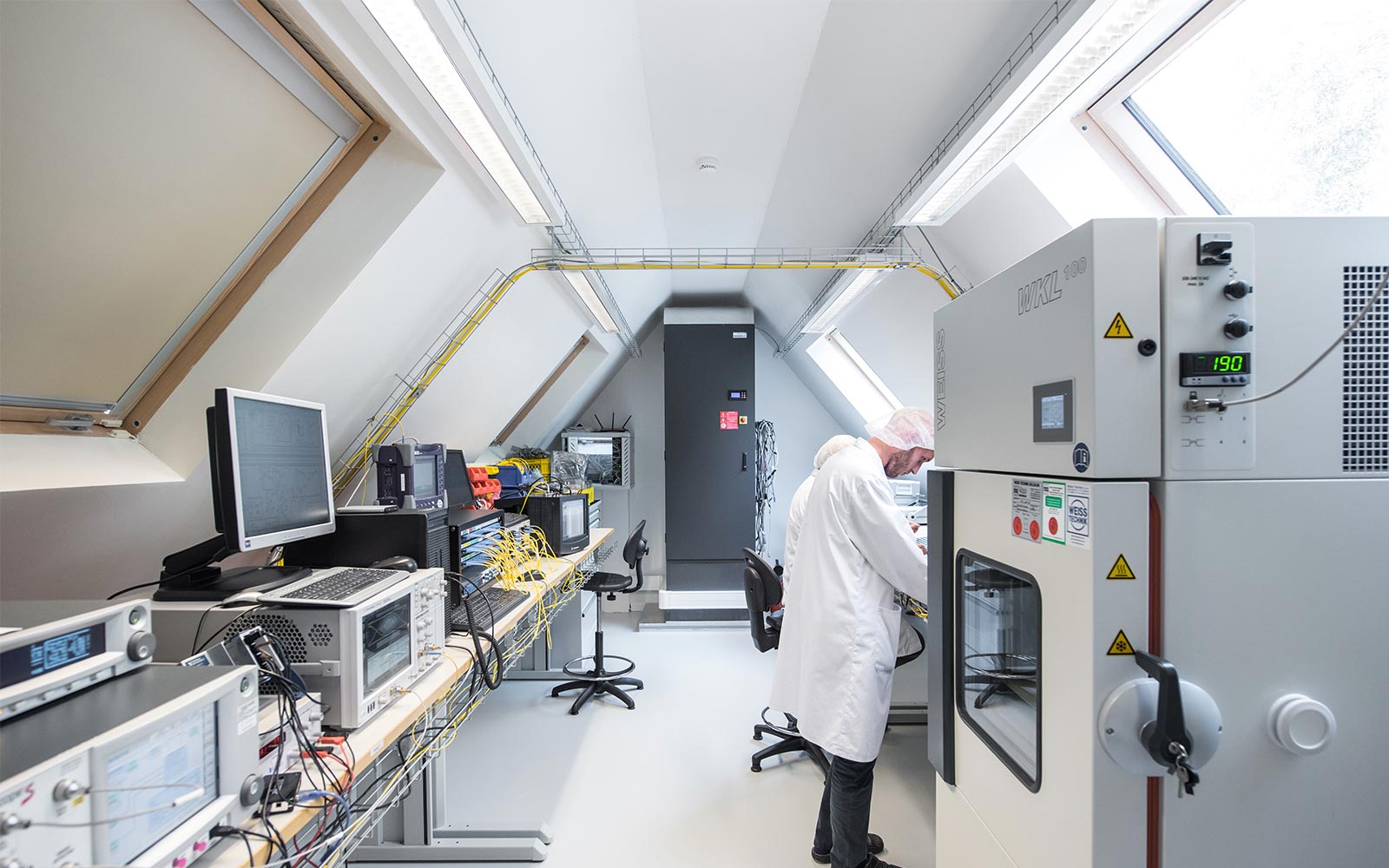

Skylane optics 's analysis & testing services includes Incoming Quality Control, Outgoing Quality Control, Laboratory and Final Testing. In order to guarantee our quality, ESD protection is mandatory. Both on production line but also during all transceiver handling steps.

An inspection process is conducted on parts when they arrive in order to ensure a high level of quality (Skylane Label).

> Control the cleanliness of the optical interfaces

> Verification of the micro-controller

> Check the light transmission and wavelength

> Packaging

Each Transceivers is labelled with :

> S/N

> P/N

> Description

Skylane Optics have full traceability from the production line to the end-customer.

This is a verification process designed to make sure that the right parts are sent out with the right label. This involves a final check.

> P/N reference

> Description by label

> Quantity

>Control of the Packaging

Our engineers go into the tiniest detail to ensure that our products operate efficiently and have a long service life:

> consumption of electrical energy in relation to the temperature;

> accuracy of DDM in relation to the temperature;

> optical power and wavelength stability in relation to the temperature;

> measurement of sensitivity at 3 temperatures;

> measurement of the dispersion penalty at 3 temperatures;

> verification of the eye pattern at 3 temperatures;

> all tests are conducted using 3 temperature tests.